The Robolube Hyrail Track Lubricator revolutionized hyrail lubrication of rail. Since 1990, Robolube Lubricators have been operating consistently in day-to-day operations in the rugged environment of the railroad industry. Many Robolube units are already at work in their second and third vehicles!

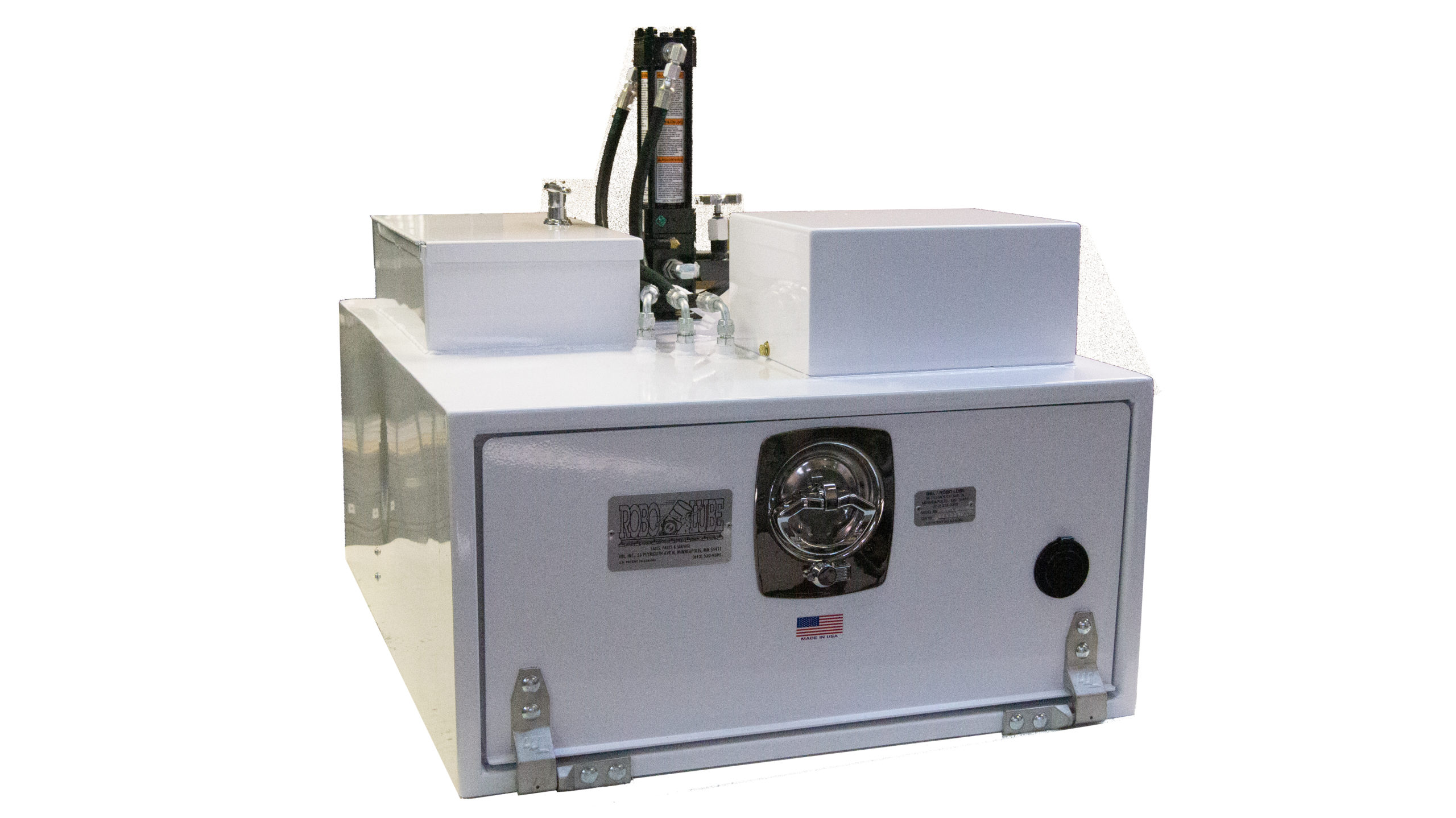

The Model MR-75 mounts easily in the back of almost any style hyrail truck with room to spare. This new innovative design allows for a lubricator to be installed on what was previously considered too light a hyrail truck to be used in a lubricating program.

Robolube’s innovative design utilizes the vehicle’s existing electrical system without the modifications that other systems require such as underhood power sources and/or additional electrical components. The Robolube design features an electric over hydraulic power source that has been field proven in day to day operations since 1990.

Since the introduction of the Robolube Hyrail Lubricator, track lubrication has evolved into an exacting process. Within this process, the amount of lubrication and its location are critical. The Robolube System utilizes small orifice sizes to reduce unnecessary grease usage and insures that only the right amount of lubricant is dispensed to the rail. With Robolube’s standard nozzle arrangement, accuracy of lubricant placement on gage face has been greatly improved. Now with the introduction of the new “Rollerlube” nozzle design acuuracy to gage face is not compormised by variables such as high elevation curves, high degree curves, weights and railgear/vehicle suspensions. Robolube introduced the first “Top of Rail” nozzle design in 1995 in response to the rail industry’s demands and Robolube continues to innovate to meet the ever changing rail lubrication environment.

The Model MR-75 was created to address one of the New Industry requirements just mentioned. The MR-75 was designed to address the continuing problem with overwweight hyrail vehicles. The MR-75 still utilizes the “Field-Proven” Robolube componenents, for a long lasting investment, only is a smaller, lighter, more econimical configuration. The reponse to this new design has been impressive.The Model MR-75 mounts easily in the back of almost any hyrail truck configuration and has the capacity to carry 75 to 125 lbs. of lubricant. Robolube’s innovative design utilizes the vehicle’s existing electrical system without the modifications that other systems require, such as underhood power sources and/or additional electrical components. The Robolube design features an electric over hydraulic power source that has been “Field Proven” in day-to-day operations since 1990.